News

Integrity casting quality, innovation to lead the future

Enhancing Product Performance Through Advanced Casting Techniques

Time: Sep 26,2025

Modern manufacturing demands precision, durability, and efficiency. As industries evolve, the need for high-quality components that can withstand extreme conditions becomes increasingly crucial. Advanced casting techniques, particularly those employed by leading investment casting foundry manufacturers, have emerged as game-changers in producing superior metal parts. These methods not only enhance product performance but also contribute to increased longevity and reliability across various sectors, from aerospace to automotive and beyond.

Table of contents:

The Impact of Investment Casting Foundry Processes on Component Strength

Optimizing Material Properties with Lost Wax Investment Casting Methods

Achieving Superior Corrosion Resistance Through Stainless Steel Precision Casting

How Silica Sol Investment Casting Contributes to Enhanced Product Longevity

The Impact of Investment Casting Foundry Processes on Component Strength

Investment casting foundry manufacturers have revolutionized the production of complex metal parts through innovative processes that significantly improve component strength. By utilizing advanced materials and precise control over the casting environment, these foundries can produce parts with exceptional structural integrity. The investment casting supplier's ability to create near-net-shape components reduces the need for extensive machining, preserving the inherent strength of the material. This process allows for the production of intricate geometries that would be challenging or impossible to achieve through traditional manufacturing methods, ultimately resulting in stronger, more reliable parts for critical applications.

Optimizing Material Properties with Lost Wax Investment Casting Methods

Lost wax investment casting suppliers have perfected techniques that optimize the material properties of cast components. This ancient method, refined for modern industrial use, allows for exceptional control over the microstructure of the final product. By carefully managing the cooling rate and solidification process, investment casting foundry manufacturers can enhance desirable material characteristics such as ductility, hardness, and fatigue resistance. The lost wax investment casting supplier's expertise in alloy selection and process parameters ensures that each component possesses the ideal combination of properties required for its intended application, leading to superior performance in the field.

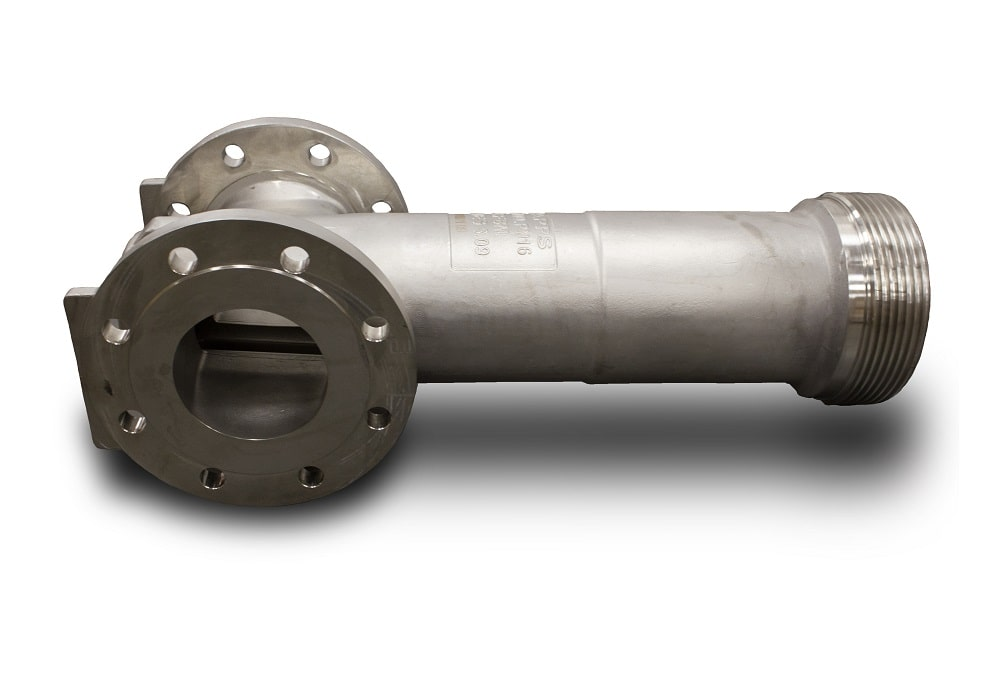

Achieving Superior Corrosion Resistance Through Stainless Steel Precision Casting

Stainless steel precision casting has become a cornerstone of producing components with exceptional corrosion resistance. Investment casting suppliers specializing in stainless steel alloys can create parts that maintain their integrity in harsh environments. The precision of the investment casting process allows for the production of complex shapes with uniform material composition, ensuring consistent corrosion resistance throughout the entire component. This level of protection is crucial for parts used in marine, chemical processing, and other corrosive environments where material degradation can lead to catastrophic failure.

How Silica Sol Investment Casting Contributes to Enhanced Product Longevity

Silica sol investment casting is a technique that has gained prominence among investment casting foundry manufacturers for its ability to produce parts with enhanced longevity. This method utilizes a silica-based binder system that results in smoother surface finishes and tighter dimensional tolerances. The improved surface quality reduces stress concentrations and potential failure points, while the dimensional accuracy ensures better fit and function in assemblies. Lost wax investment casting suppliers employing silica sol technology can create components that not only perform better initially but also maintain their performance characteristics over extended periods, significantly increasing the overall lifespan of the final product.

Advanced casting techniques have ushered in a new era of product performance and reliability. Investment casting foundry manufacturers and suppliers continue to push the boundaries of what's possible in metal component production. By leveraging processes such as lost wax investment casting and silica sol investment casting, these specialists create parts that excel in strength, material properties, corrosion resistance, and longevity. As industries demand ever-higher standards of quality and performance, the role of advanced casting techniques in meeting these challenges becomes increasingly vital, ensuring that products not only meet but exceed the expectations of today's demanding applications.

More News

Sep 26,2025

Enhancing Product Performance Through Advanced Casting Techniques

Modern manufacturing demands precision, durability, and efficiency.

Sep 26,2025

Elevating Product Quality Through Stainless Steel Precision Casting

Precision casting has revolutionized the manufacturing landscape, offering unparalleled accuracy and versatility in component production.

Sep 24,2025

Lowering Your Casting Costs: A Comparative Analysis of NovaCast and YiXin Machinery

For any business seeking a reliable lost wax investment casting supplier, balancing precision with cost is the ultimate challenge.