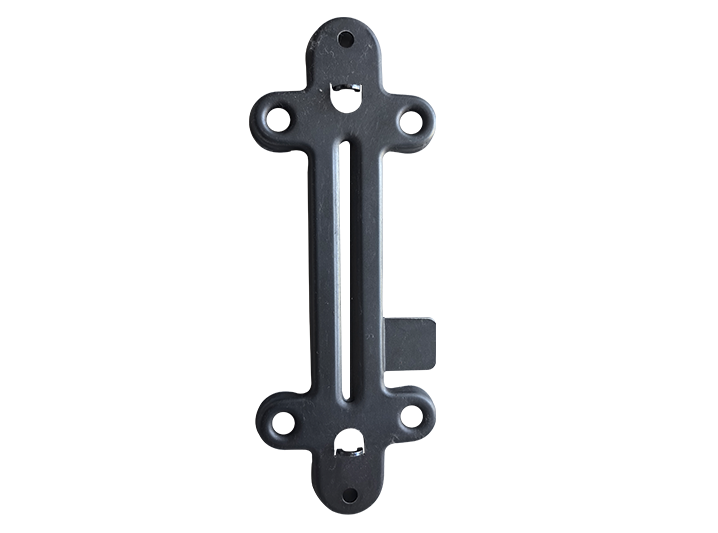

Water glass casting series products

Product Details

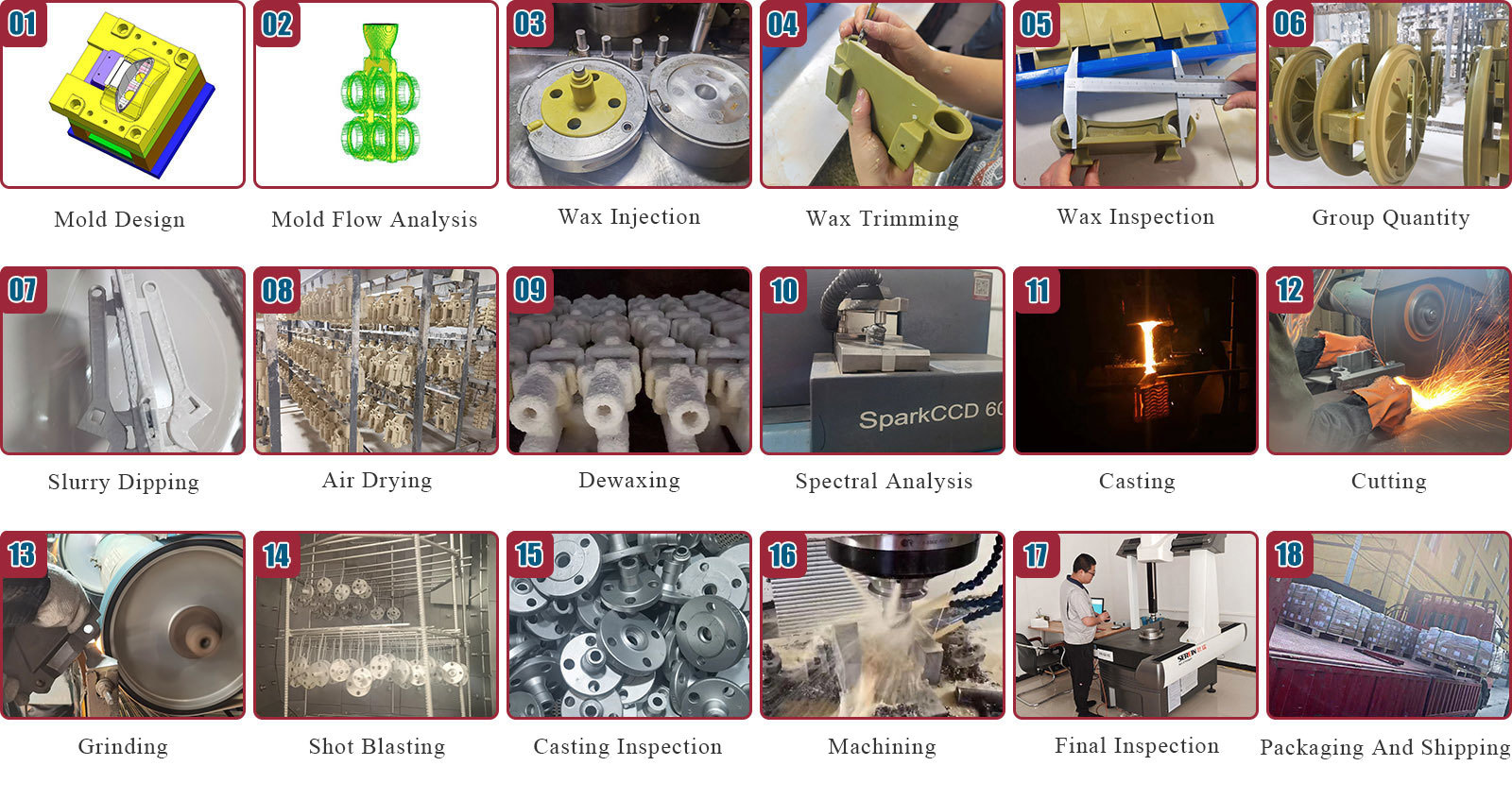

Production process

Comprehensive Alloy Capability with Water Glass Casting

YiXin Machinery’s water glass casting series supports a wide range of materials: carbon steel, low-alloy and medium-alloy steel, high-manganese steel, stainless steel, heat-resistant steel, and dual-phase steel. Production adheres to global standards such as GB, ASTM, AISI, DIN, NF, JIS, and BS, assuring customers receive components meeting stringent quality expectations.

Strict Dimensional Accuracy Across Sizes

Our casting capability spans single-part weights from 0.01 kg to 80 kg and maximum dimensions of 800 × 600 × 600 mm. Dimensional tolerances are tightly controlled: for parts of size 0–9 mm, linear tolerance is 0.3 mm; perpendicularity 0.15 mm; flatness 0.2 mm; parallelism 0.25 mm; coaxiality/cylindricity 0.30 mm. Tolerances increase proportionally up to sizes of 400–800 mm, with linear tolerance at 4.0 mm and corresponding tolerances for other metrics—ensuring precise and reliable precision casting parts.

Scalable Production with Efficient Lead Times

Minimum order quantity starts at 100 pieces or 100 kg. Custom mapping or sample preparation requires 20–30 days, while full batch production completes in 35–50 days. Guided by principles of customer-first service, integrity, quality assurance, and reasonable pricing, YiXin Machinery ensures dependable and professional support throughout the water glass foundry production process.

Product Advantages

Extensive Material Coverage and Standards Compliance

YiXin Machinery delivers water glass casting across diverse alloys—including stainless, heat-resistant, and dual-phase steels—under recognized standards like GB, ASTM, DIN, and JIS. This versatility suits a broad spectrum of industry demands with consistency and precision.

Precision Across All Geometry Dimensions

Adherence to stringent tolerances for linear dimensions, perpendicularity, flatness, and cylindricity ensures each precision casting part meets accuracy expectations across batch production. This reduces rework and enhances fit in assembly processes.

Agile Production Flexibility with Reliability

With low trade thresholds and clear lead time structure (20–30 days for samples, 35–50 days for batches), YiXin Machinery balances responsiveness with quality control, ensuring scalable and trustworthy supply from prototype to production.

Production capacity

Execute standards: GB, ASTM, AISI, DIN, NF, JIS, BS,

Producable materials: carbon steel, low alloy steel, medium alloy steel, high manganese steel, stainless steel, heat-resistant steel, dual-phase steel

Product single weight and size range: single weight 0.01 kg-80kg, maximum size 800mm * 600mm * 600mm.

Dimensional accuracy is guaranteed:

| Basic size range of castings (mm) | Linear Dimensions Tolerance (mm) |

Perpendicularity and straightness tolerance (mm) | Flatness, ovality tolerance (mm) | Parallelism, symmetry tolerance (mm) | Coaxiality, cylindricity tolerance (mm) |

| 0-9 | 0.3 | 0.15 | 0.2 | 0.25 | 0.30 |

| > 6-10 | 0.36 | 0.18 | 0.25 | 0.30 | 0.35 |

| > 10-18 | 0.44 | 0.25 | 0.40 | 0.40 | 0.50 |

| > 18-30 | 0.52 | 0.30 | 0.50 | 0.50 | 0.60 |

| > 30-50 | 0.8 | 0.40 | 0.60 | 0.70 | 0.80 |

| > 50-80 | 0.9 | 0.60 | 0.80 | 1.00 | 1.10 |

| 80-120 | 1.1 | 0.80 | 1.00 | 1.30 | 1.30 |

| > 120-180 | 1.6 | 1.10 | 1.30 | 1.80 | 1.80 |

| > 180-250 | 2.4 | 1.50 | 1.80 | 2.50 | 2.40 |

| > 250-315 | 2.6 | 1.90 | 2.30 | 3.00 | 3.00 |

| > 315-400 | 3.6 | 2.40 | 2.90 | 3.80 | 3.80 |

| > 400-800 | 4.0 | 3.00 | 3.40 | 4.40 | 4.40 |

Minimum quantity: 100 pieces or 100kg

To map or sample customization, sample time: 20-30 days, mass production time: 35-50 days/batch

Cooperation Process

People-oriented, based on virtue, quality as the root

Yuankun Machinery takes the customer first as the purpose, the quality of survival, the integrity of the management concept of development, heavy contract, keep the reputation, with high-quality products, reasonable prices to provide you with perfect service.

Benchmarking products

immediate consultation

Note: If you have any questions about our products and services, please feel free to contact us.