Machining series products

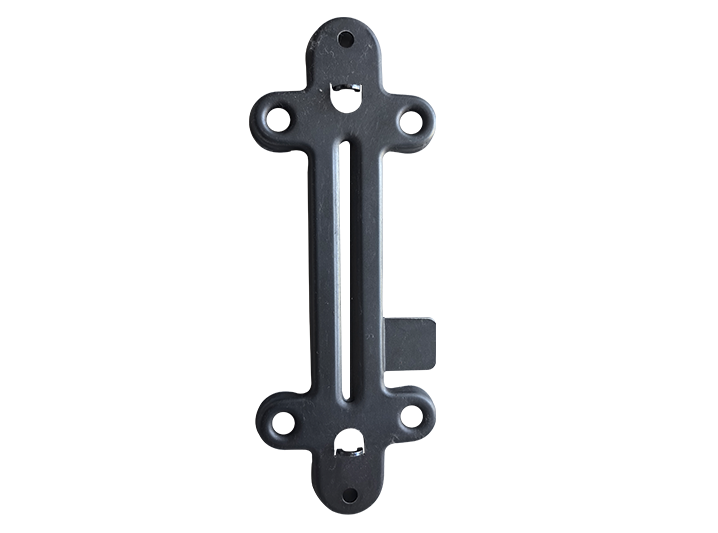

Product Details

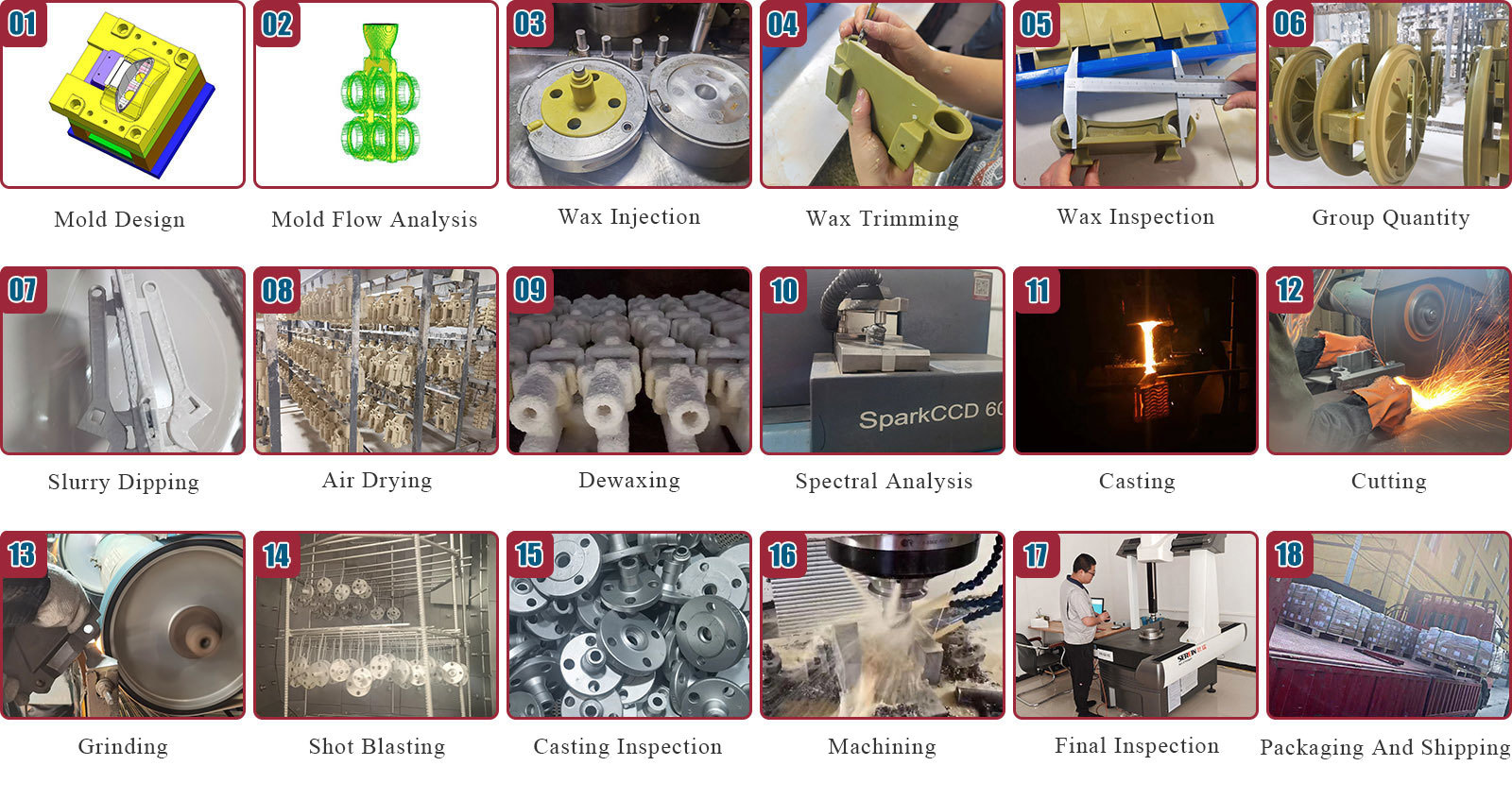

Production process

High-End Machining Equipment and Technical Capability

YiXin Machinery’s Machining Series, leveraging advanced equipment such as machining centers, CNC lathes, CNC milling machines, and CNC grinders, delivers professional precision CNC machining services that ensure the consistent production of high-quality parts. Supported by professional inspection systems—including three-coordinate measuring instruments, spectrometers, and magnetic particle flaw detectors—and steered under a strict management system, our capabilities reflect the standards expected from a leading precision CNC machining factory.

Diverse Component Output and Rigorous Quality Assurance

Our CNC precision machining process produces precise components designed for hardware applications. The precision equipment and monitoring allow us to achieve accurate dimensions and surface finishes essential for tight-fitting parts and assemblies, reinforcing reliability and consistency across batch production.

Integrated Manufacturing and Service Excellence

As a full-spectrum precision CNC machining services provider, YiXin Machinery coordinates from initial design input through machining and quality validation, offering secure, time-efficient delivery, competitive pricing, and performance-driven execution—hallmarks of a trusted CNC machining partner.

Product Advantages

1. Advanced CNC Capabilities

With a wide array of CNC equipment—machining centers, lathes, milling machines, grinders—YiXin Machinery meets diverse machining demands for parts requiring intricate detail and high fidelity, reinforcing our position as a premier CNC precision machining provider.

2. Robust Quality Control

Employing professional testing and inspection tools such as coordinate measuring systems, spectrometers, and magnetic particle detectors—within a strict management system—enables YiXin to deliver parts with reliable performance and precision, reflecting our commitment to precision CNC machining services.

3. Streamlined Service and Production Efficiency

Combining in-house machining expertise with steadfast quality management practices, YiXin offers an optimal mix of price, speed, and precision—ideal for clients needing dependable hardware accessories from a reputable CNC machining factory.

Production capacity

Execute standards: GB, ASTM, AISI, DIN, NF, JIS, BS,

Producable materials: carbon steel, low alloy steel, medium alloy steel, high manganese steel, stainless steel, heat-resistant steel, dual-phase steel

Product single weight and size range: single weight 0.01 kg-80kg, maximum size 800mm * 600mm * 600mm.

Dimensional accuracy is guaranteed:

| Basic size range of castings (mm) | Linear Dimensions Tolerance (mm) |

Perpendicularity and straightness tolerance (mm) | Flatness, ovality tolerance (mm) | Parallelism, symmetry tolerance (mm) | Coaxiality, cylindricity tolerance (mm) |

| 0-9 | 0.3 | 0.15 | 0.2 | 0.25 | 0.30 |

| > 6-10 | 0.36 | 0.18 | 0.25 | 0.30 | 0.35 |

| > 10-18 | 0.44 | 0.25 | 0.40 | 0.40 | 0.50 |

| > 18-30 | 0.52 | 0.30 | 0.50 | 0.50 | 0.60 |

| > 30-50 | 0.8 | 0.40 | 0.60 | 0.70 | 0.80 |

| > 50-80 | 0.9 | 0.60 | 0.80 | 1.00 | 1.10 |

| 80-120 | 1.1 | 0.80 | 1.00 | 1.30 | 1.30 |

| > 120-180 | 1.6 | 1.10 | 1.30 | 1.80 | 1.80 |

| > 180-250 | 2.4 | 1.50 | 1.80 | 2.50 | 2.40 |

| > 250-315 | 2.6 | 1.90 | 2.30 | 3.00 | 3.00 |

| > 315-400 | 3.6 | 2.40 | 2.90 | 3.80 | 3.80 |

| > 400-800 | 4.0 | 3.00 | 3.40 | 4.40 | 4.40 |

Minimum quantity: 100 pieces or 100kg

To map or sample customization, sample time: 20-30 days, mass production time: 35-50 days/batch

Cooperation Process

People-oriented, based on virtue, quality as the root

Yuankun Machinery takes the customer first as the purpose, the quality of survival, the integrity of the management concept of development, heavy contract, keep the reputation, with high-quality products, reasonable prices to provide you with perfect service.

Benchmarking products

immediate consultation

Note: If you have any questions about our products and services, please feel free to contact us.