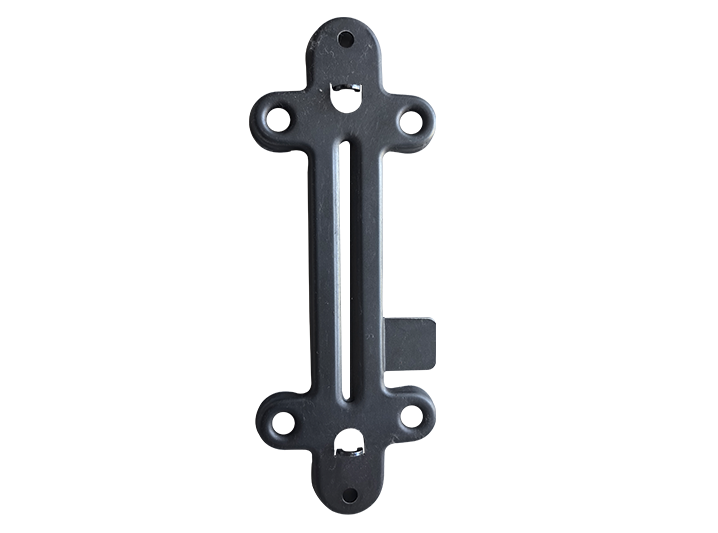

Water glass casting series products

Product Details

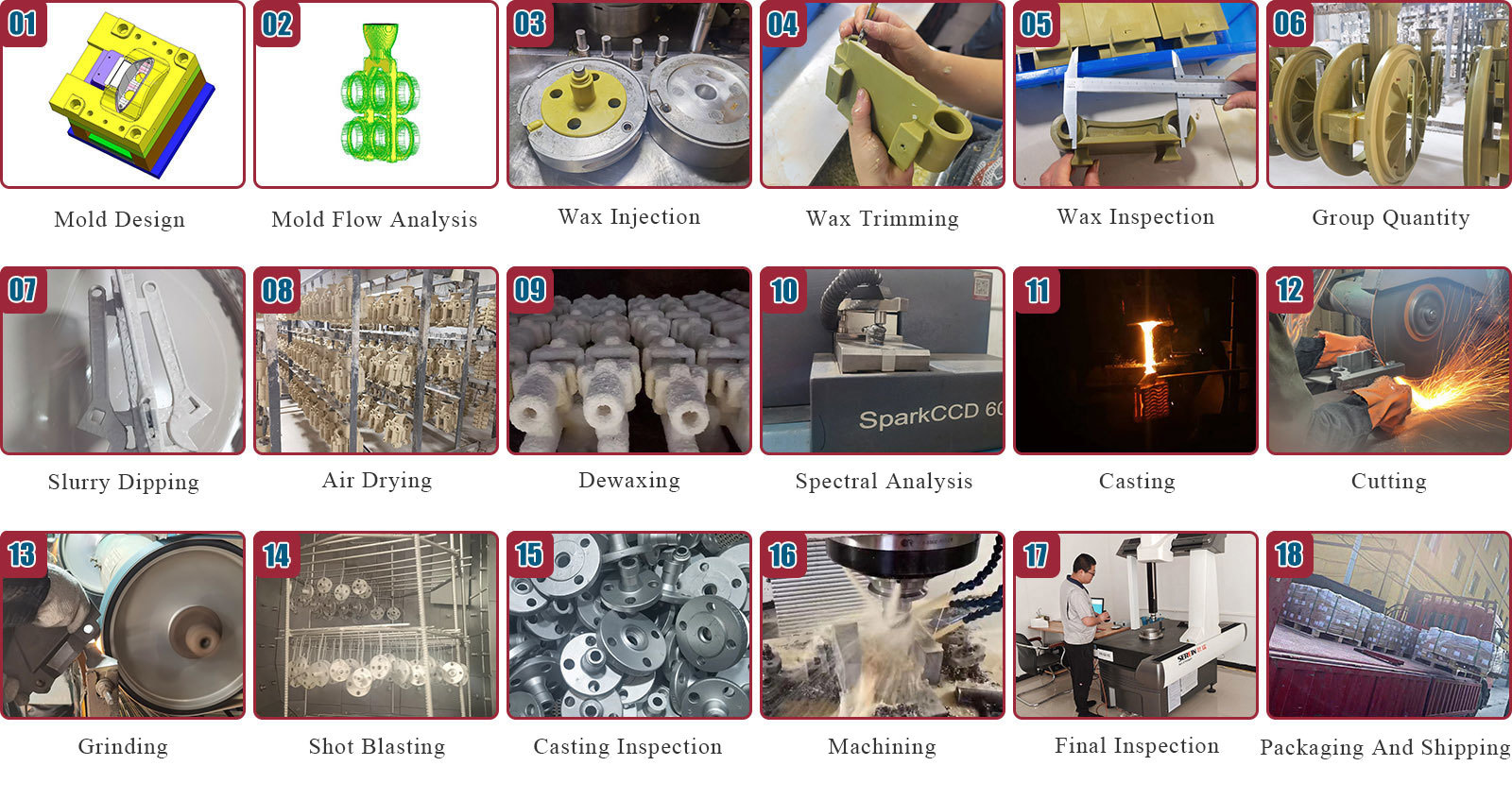

Production process

Wide Alloy Support and Professional Process

YiXin Machinery provides high-quality water glass precision casting, covering a comprehensive range of casting materials including carbon steel, low and medium alloy steel, stainless steel, high-manganese steel, heat-resistant steel, and dual-phase steel. We manufacture in accordance with major international standards such as GB, ASTM, AISI, DIN, NF, JIS, and BS. Our facility is equipped with advanced machining centers, CNC lathes, milling machines, grinding machines, and professional inspection tools including coordinate measuring machines, spectrometers, and magnetic particle flaw detectors. This ensures that every part produced in our water glass foundry meets exacting quality and structural specifications.

Precision Tolerances and Dimensional Stability

Our casting capabilities range from 0.01 kg to 80 kg per part, with maximum dimensions of 800 × 600 × 600 mm. Dimensional tolerances are meticulously managed: for linear sizes of 0–9 mm, the tolerance is 0.3 mm, increasing proportionally up to 4.0 mm for 400–800 mm. Additional parameters such as perpendicularity, flatness, parallelism, symmetry, coaxiality, and cylindricity are all maintained under strict specifications. This tight control over casting accuracy allows YiXin Machinery to deliver reliable precision casting parts for high-demand applications.

Efficient Delivery and Scalable Orders

YiXin Machinery operates with an MOQ of 100 pieces or 100 kg. Sample customization typically requires 20–30 days, while standard batch production can be completed in 35–50 days. Our production model is designed to accommodate both prototyping and scalable industrial orders. We adhere to a customer-first approach and uphold strict quality control, reliable timelines, and competitive pricing—ensuring full trust and satisfaction as your preferred precision casting company.

Product Advantages

Wide Range of Supported Alloys

Our water glass foundry handles an extensive selection of materials including carbon steel, alloy steel, stainless steel, and other specialized grades. This material diversity allows us to support clients across multiple industries, from energy to construction, with cost-effective and durable casting solutions.

Superior Geometric Control

YiXin Machinery applies high-precision quality control standards to manage linear tolerances, perpendicularity, flatness, and symmetry across casting sizes. Our use of automated CNC equipment and professional inspection ensures that every component aligns with client specifications, reducing the need for additional machining or post-processing.

Flexible Production with Reliable Turnaround

With quick turnaround on samples and predictable batch production cycles, we help customers streamline time-to-market. Whether for high-volume production or custom orders, YiXin Machinery’s precision casting parts are delivered efficiently and in strict accordance with required dimensions and mechanical properties.

Production capacity

Execute standards: GB, ASTM, AISI, DIN, NF, JIS, BS,

Producable materials: carbon steel, low alloy steel, medium alloy steel, high manganese steel, stainless steel, heat-resistant steel, dual-phase steel

Product single weight and size range: single weight 0.01 kg-80kg, maximum size 800mm * 600mm * 600mm.

Dimensional accuracy is guaranteed:

| Basic size range of castings (mm) | Linear Dimensions Tolerance (mm) |

Perpendicularity and straightness tolerance (mm) | Flatness, ovality tolerance (mm) | Parallelism, symmetry tolerance (mm) | Coaxiality, cylindricity tolerance (mm) |

| 0-9 | 0.3 | 0.15 | 0.2 | 0.25 | 0.30 |

| > 6-10 | 0.36 | 0.18 | 0.25 | 0.30 | 0.35 |

| > 10-18 | 0.44 | 0.25 | 0.40 | 0.40 | 0.50 |

| > 18-30 | 0.52 | 0.30 | 0.50 | 0.50 | 0.60 |

| > 30-50 | 0.8 | 0.40 | 0.60 | 0.70 | 0.80 |

| > 50-80 | 0.9 | 0.60 | 0.80 | 1.00 | 1.10 |

| 80-120 | 1.1 | 0.80 | 1.00 | 1.30 | 1.30 |

| > 120-180 | 1.6 | 1.10 | 1.30 | 1.80 | 1.80 |

| > 180-250 | 2.4 | 1.50 | 1.80 | 2.50 | 2.40 |

| > 250-315 | 2.6 | 1.90 | 2.30 | 3.00 | 3.00 |

| > 315-400 | 3.6 | 2.40 | 2.90 | 3.80 | 3.80 |

| > 400-800 | 4.0 | 3.00 | 3.40 | 4.40 | 4.40 |

Minimum quantity: 100 pieces or 100kg

To map or sample customization, sample time: 20-30 days, mass production time: 35-50 days/batch

Cooperation Process

People-oriented, based on virtue, quality as the root

Yuankun Machinery takes the customer first as the purpose, the quality of survival, the integrity of the management concept of development, heavy contract, keep the reputation, with high-quality products, reasonable prices to provide you with perfect service.

Benchmarking products

immediate consultation

Note: If you have any questions about our products and services, please feel free to contact us.