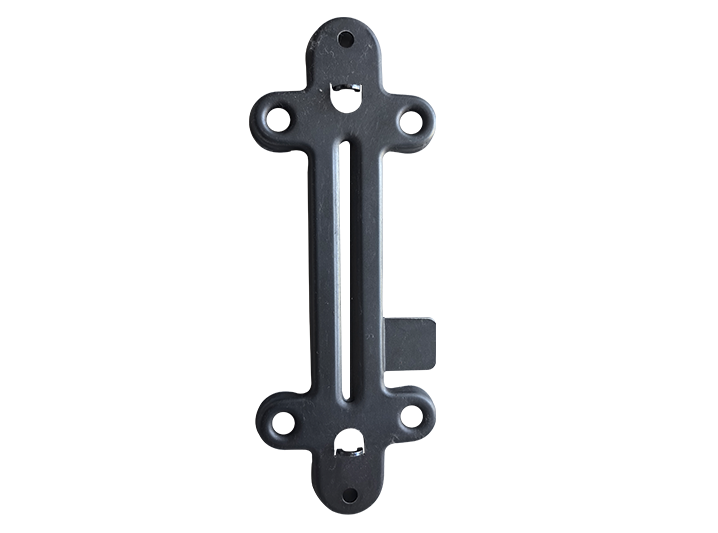

Silica Sol Precision Casting Series Products

Product Details

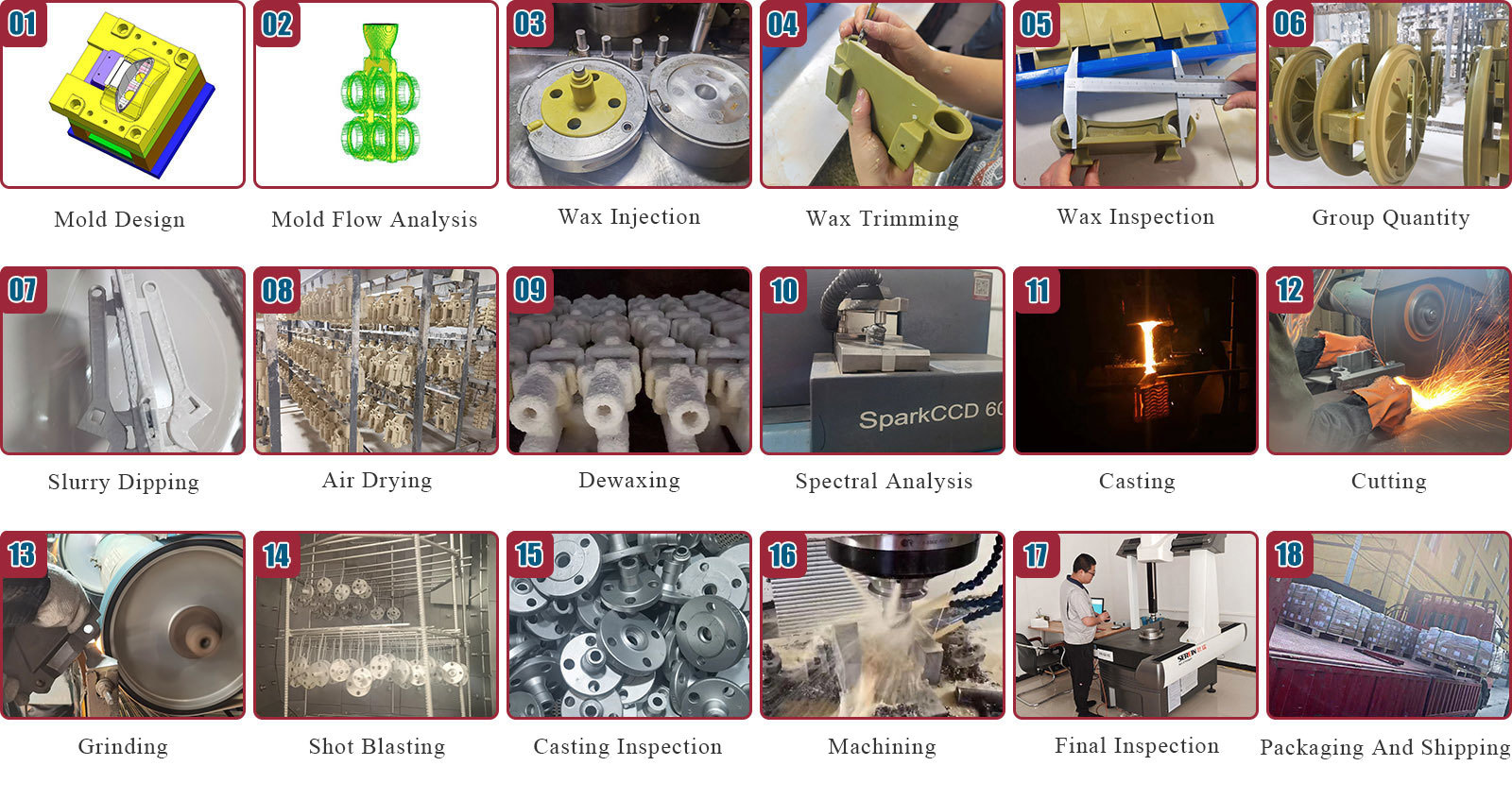

Production process

Rigorous Process with High Alloy Versatility

YiXin Machinery’s silica sol precision casting process supports a wide selection of materials—including carbon steel, alloy steel, stainless steel, heat-resistant steel, high‑manganese steel, and dual‑phase steel—ensuring versatility as one of the leading precision casting manufacturers. This method produces complex parts with excellent material integrity, from small components weighing 0.01 kg up to 80 kg and dimensions up to 800 × 600 × 600 mm. The combination of advanced processes and diverse alloy support provides clients with reliable, adaptable casting outcomes.

Stringent Dimensional Accuracy and Quality Assurance

Our investment casting services deliver precise tolerances across key dimensions: for linear sizes up to 9 mm, tolerances start at 0.3 mm and scale logically for larger parts—up to 4.0 mm at sizes between 400–800 mm. Perpendicularity, flatness, parallelism, symmetry, coaxiality, and cylindricity are tightly controlled. Backed by rigorous testing with coordinate measuring machines, spectrometers, and magnetic particle flaw detectors, YiXin Machinery ensures each casting aligns with specification and quality expectations.

Efficient Capacity with Responsive Delivery

As foremost precision casting manufacturers, we offer scalable production with a minimum order of only 100 pieces or 100 kg. Sample customization—including pattern and mapping—typically completes within 20–30 days, while mass production takes 35–50 days per batch. This balance of precision, speed, and capacity allows clients to receive high‑quality castings efficiently, tailored to their project timelines and production scales.

Product Advantages

Broad Alloy Capability and Consistent Quality

YiXin Machinery excels in investment casting across a broad spectrum of alloys—carbon steel, low‑ and medium‑alloy steel, stainless steel, heat‑resistant grades, high‑manganese, and dual‑phase steels. This versatility allows us to meet varied application needs without compromising on material integrity or casting consistency, strengthening our standing among precision casting manufacturers.

Tight Tolerance and Dimensional Reliability

The silica sol precision casting technique ensures controlled dimensional tolerances across all critical metrics—linear, perpendicularity, flatness, symmetry, and cylindricity. With professionally calibrated measurement systems and flaw detection, each casting aligns with client specifications, minimizing post-processing and improving production reliability.

Streamlined Custom Production Workflow

YiXin Machinery’s investment casting services enable streamlined production workflows. Sample stages complete in 20–30 days; mass batch production follows within 35–50 days. Combined with our minimum order requirement of just 100 pieces or 100 kg, our process is both responsive and economical—even for custom or low-volume orders—without sacrificing accuracy or quality.

Production capacity

Execute standards: GB, ASTM, AISI, DIN, NF, JIS, BS,

Producable materials: carbon steel, low alloy steel, medium alloy steel, high manganese steel, stainless steel, heat-resistant steel, dual-phase steel

Product single weight and size range: single weight 0.01 kg-80kg, maximum size 800mm * 600mm * 600mm.

Dimensional accuracy is guaranteed:

| Basic size range of castings (mm) | Linear Dimensions Tolerance (mm) |

Perpendicularity and straightness tolerance (mm) | Flatness, ovality tolerance (mm) | Parallelism, symmetry tolerance (mm) | Coaxiality, cylindricity tolerance (mm) |

| 0-9 | 0.3 | 0.15 | 0.2 | 0.25 | 0.30 |

| > 6-10 | 0.36 | 0.18 | 0.25 | 0.30 | 0.35 |

| > 10-18 | 0.44 | 0.25 | 0.40 | 0.40 | 0.50 |

| > 18-30 | 0.52 | 0.30 | 0.50 | 0.50 | 0.60 |

| > 30-50 | 0.8 | 0.40 | 0.60 | 0.70 | 0.80 |

| > 50-80 | 0.9 | 0.60 | 0.80 | 1.00 | 1.10 |

| 80-120 | 1.1 | 0.80 | 1.00 | 1.30 | 1.30 |

| > 120-180 | 1.6 | 1.10 | 1.30 | 1.80 | 1.80 |

| > 180-250 | 2.4 | 1.50 | 1.80 | 2.50 | 2.40 |

| > 250-315 | 2.6 | 1.90 | 2.30 | 3.00 | 3.00 |

| > 315-400 | 3.6 | 2.40 | 2.90 | 3.80 | 3.80 |

| > 400-800 | 4.0 | 3.00 | 3.40 | 4.40 | 4.40 |

Minimum quantity: 100 pieces or 100kg

To map or sample customization, sample time: 20-30 days, mass production time: 35-50 days/batch

Cooperation Process

People-oriented, based on virtue, quality as the root

Yuankun Machinery takes the customer first as the purpose, the quality of survival, the integrity of the management concept of development, heavy contract, keep the reputation, with high-quality products, reasonable prices to provide you with perfect service.

Benchmarking products

immediate consultation

Note: If you have any questions about our products and services, please feel free to contact us.