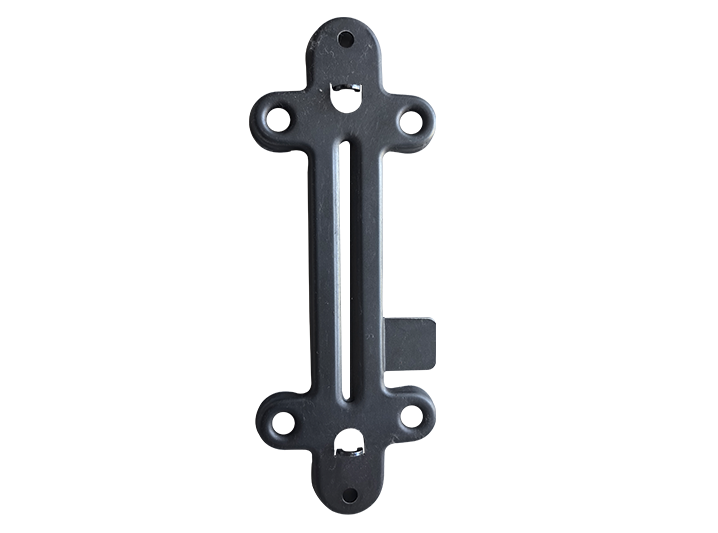

Silica Sol Precision Casting Series Products

Product Details

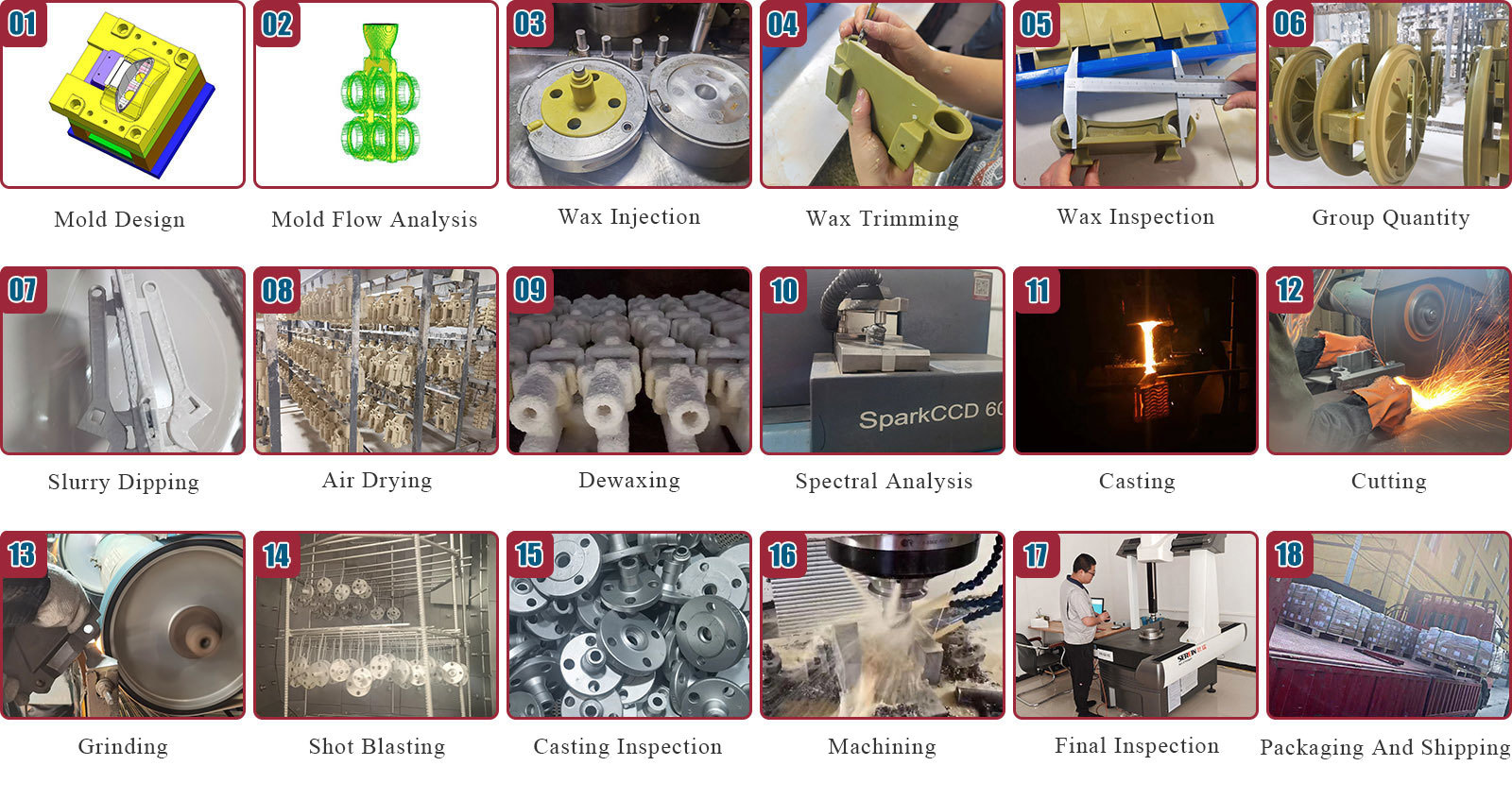

Production process

Engineered Precision and Process Excellence

At YiXin Machinery, our investment casting services are built on the silica sol process, known for producing intricate parts with high dimensional accuracy and minimal surface defects. Each stage, from wax pattern preparation to shell construction and metal pouring, is closely monitored to meet rigorous quality benchmarks. This ensures our precision investment casting results in components that are structurally sound, repeatable, and near-net shape, significantly reducing the need for post-processing.

Flexible Applications Across Alloys and Industries

YiXin Machinery specializes in precision investment casting for a wide array of metal alloys, including stainless steel, heat-resistant steel, and non-ferrous alloys. These materials are cast into complex geometries suitable for aerospace parts, mechanical hardware, automotive components, and energy systems. Through our advanced investment casting services, we provide tailored casting solutions that meet demanding performance and environmental conditions.

Scalable, Cost-Controlled Production

Our foundry capabilities allow us to efficiently manage both prototype and mass production volumes. By leveraging silica sol precision casting, we minimize material waste and reduce machining requirements, translating into cost savings and shorter lead times. Clients benefit from our streamlined processes, reliable delivery schedules, and commitment to high standards, making us a competitive choice among precision casting manufacturers.

Product Advantages

Exceptional Casting Accuracy

Utilizing the silica sol method, YiXin Machinery consistently achieves tight dimensional tolerances and smooth surface finishes. This level of detail is critical for high-performance applications, reducing the need for further machining and ensuring consistent part functionality from batch to batch.

Broad Alloy Compatibility

Our investment casting services are suitable for a variety of ferrous and non-ferrous alloys. Whether casting corrosion-resistant stainless steel for fluid systems or high-strength steel for mechanical assemblies, we maintain material integrity through a controlled and clean process that preserves each alloy's physical properties.

Reliable and Customizable Output

YiXin Machinery delivers repeatable, high-precision components according to client specifications. From design assistance to final inspection, our team provides full-service project support. We offer flexible production planning, adapting quickly to design changes or varying batch sizes, ensuring your product development remains agile and on-budget.

Production capacity

Execute standards: GB, ASTM, AISI, DIN, NF, JIS, BS,

Producable materials: carbon steel, low alloy steel, medium alloy steel, high manganese steel, stainless steel, heat-resistant steel, dual-phase steel

Product single weight and size range: single weight 0.01 kg-80kg, maximum size 800mm * 600mm * 600mm.

Dimensional accuracy is guaranteed:

| Basic size range of castings (mm) | Linear Dimensions Tolerance (mm) |

Perpendicularity and straightness tolerance (mm) | Flatness, ovality tolerance (mm) | Parallelism, symmetry tolerance (mm) | Coaxiality, cylindricity tolerance (mm) |

| 0-9 | 0.3 | 0.15 | 0.2 | 0.25 | 0.30 |

| > 6-10 | 0.36 | 0.18 | 0.25 | 0.30 | 0.35 |

| > 10-18 | 0.44 | 0.25 | 0.40 | 0.40 | 0.50 |

| > 18-30 | 0.52 | 0.30 | 0.50 | 0.50 | 0.60 |

| > 30-50 | 0.8 | 0.40 | 0.60 | 0.70 | 0.80 |

| > 50-80 | 0.9 | 0.60 | 0.80 | 1.00 | 1.10 |

| 80-120 | 1.1 | 0.80 | 1.00 | 1.30 | 1.30 |

| > 120-180 | 1.6 | 1.10 | 1.30 | 1.80 | 1.80 |

| > 180-250 | 2.4 | 1.50 | 1.80 | 2.50 | 2.40 |

| > 250-315 | 2.6 | 1.90 | 2.30 | 3.00 | 3.00 |

| > 315-400 | 3.6 | 2.40 | 2.90 | 3.80 | 3.80 |

| > 400-800 | 4.0 | 3.00 | 3.40 | 4.40 | 4.40 |

Minimum quantity: 100 pieces or 100kg

To map or sample customization, sample time: 20-30 days, mass production time: 35-50 days/batch

Benchmarking products

immediate consultation

Note: If you have any questions about our products and services, please feel free to contact us.